Philosophy:

We believe good design is key to business success. Our design services aim to create products that are aesthetically pleasing, practical, meet market demands, and are efficient to produce.

Process & Capabilities:

- Market & Needs Analysis: In-depth research into the latest trends in Southeast Asian target markets, consumer behavior, and specific client requirements (functionality, budget, brand image).

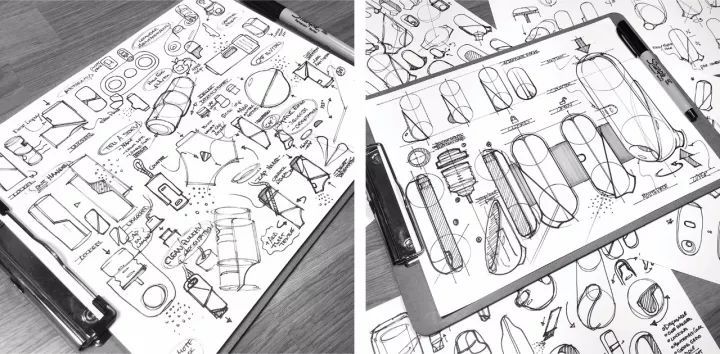

- Concept Design & Visualization: Our designers transform your ideas into preliminary sketches, 2D renderings, and realistic 3D models, allowing you to preview the final effect before production. We are proficient in professional software like AutoCAD, SolidWorks, Rhino, Keyshot, etc.

- Material Science & Selection: Based on a deep understanding of acrylic (various grades, colors, properties), wire (diameter, material, surface treatment), and injection plastics (PP, PS, ABS, PETG, etc.), we recommend the materials best suited for the product's application and cost targets.

- Structural Engineering & Optimization: Ensuring product structure is stable, durable, easy to assemble (if needed), and considers ergonomics. We perform mechanical analysis (if applicable) and optimize designs to reduce material waste and production difficulty.

- Rapid Prototyping: Offering rapid sampling services (3D printing, handmade samples, simple mold trials) so you can touch, test, and confirm design details before mass production.

- Mold Design & Manufacturing (for Injection Molding): For injection molded products, we collaborate with experienced mold factories for precision mold design, ensuring product dimensional accuracy, surface finish, and production efficiency. We analyze mold flow to optimize gating and cooling systems.

Professional Embodiment: We focus on details, such as achieving seamless acrylic bonding, ensuring the strength and aesthetics of wire welds, and controlling shrinkage and flash removal in injection molded products. Our designs consider not only appearance but are deeply integrated with considerations for production processes and cost control.